Most people only notice a staircase when something goes wrong: a squeak that gets louder, a tread that feels soft, a railing that no longer sits straight. Stairs face constant traffic, grit from shoes, wet weather near entry points, and knocks from moving furniture. That hard use is why many owners choose metal staircases when they want a long-lasting build with less upkeep.

Why timber and concrete often age faster

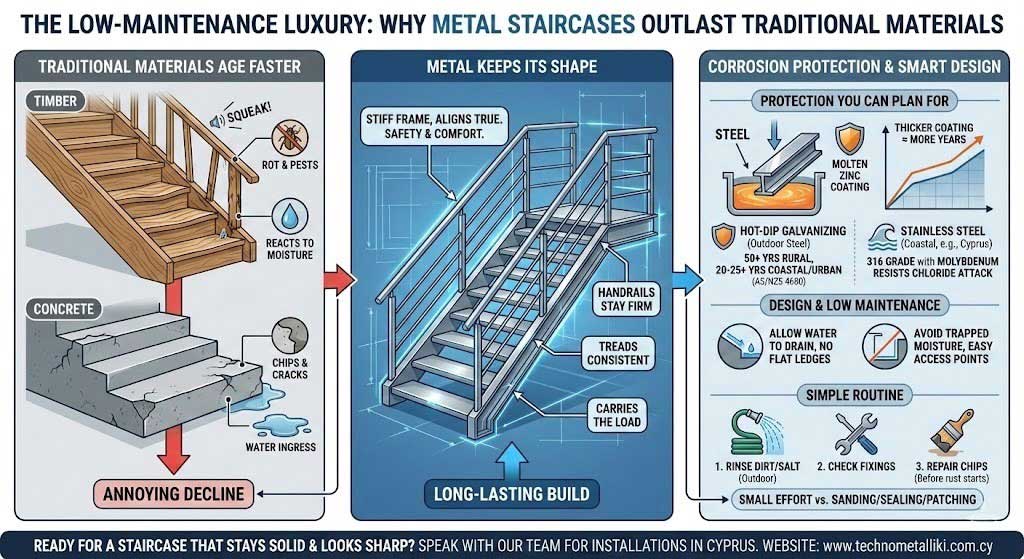

Timber reacts to moisture. It can swell, shrink, and loosen at joints, which leads to squeaks and uneven treads. In damp areas it can also attract decay and pests. Concrete avoids rot, yet edges can chip and cracks can let water in. The decline is usually slow, then suddenly annoying.

Metal keeps its shape

Steel and aluminium stairs can be built as a stiff frame. Stringers and connections carry the load and keep the stair aligned. When the structure stays true, handrails stay firm and tread heights stay consistent, which helps with safety and comfort. Over the long term, the key risk for most outdoor metal stairs is corrosion.

Corrosion protection you can plan for

Hot-dip galvanising is widely used for outdoor steel. The steel is dipped in molten zinc, creating a protective coating.

ISO 1461 states that the duration of corrosion protection is approximately proportional to coating thickness. Put simply, more coating usually means more years before maintenance.

In Australia, specifications often refer to AS/NZS 4680 for hot-dip galvanised coatings on fabricated steelwork. The Galvanizers Association of Australia reports that galvanised coatings on typical structural members can last well over 50 years in many rural environments, and around 20 to 25 years or more in severe urban and coastal exposure.

Salt air, trapped moisture, and sheltered corners can shorten the time before first maintenance.

Design details that extend life

Long life often comes down to small choices: allowing water to drain, avoiding flat ledges where grime sits, and keeping closed sections from trapping moisture. A well-placed access point can also make inspections and touch-ups easy, which means issues get fixed early rather than ignored.

Choosing the right finish

Galvanising will suit exposed exterior stairs. Where colour is needed, many projects add a second coating over galvanising. Indoors, powder coating is common because it looks neat and is easy to wipe clean.

For coastal sites, stainless steel may be a better match. 316 stainless contains molybdenum and has better resistance to chloride attack than 304. This is often relevant in Mediterranean climates, including many staircases projects in Cyprus where sea air can travel inland.

What “low maintenance” really looks like

Metal stairs still need basic care, but the routine is simple:

- Rinse off dirt and salt on outdoor stairs.

- Check fixings and joints from time to time.

- Repair chips in paint or powder coating before rust starts under the edge.

That kind of maintenance is small compared with sanding and resealing timber, or patching damaged concrete.

Why it feels like a smart long-term choice

A well-made metal stair stays square and dependable for years.

The cost is not just the build price, it is also the time you do not spend on repairs, and the disruption you avoid. For homes and businesses alike, that steady performance is the quiet luxury.

Ready to plan a stair that stays solid and looks sharp for years? Speak with our team for staircase installations in Cyprus and get clear advice on materials, finishes, and the right layout for your space.

Frequently Asked Questions

1. How long do galvanised steel stairs last outdoors?

It depends on the environment and the coating thickness. ISO 1461 links protection time to coating thickness, so the specification matters. As a broad guide, the Galvanizers Association of Australia reports well over 50 years in many rural settings and around 20 to 25 years or more in severe urban and coastal exposure. Sheltered, damp areas may need attention sooner.

2. Do metal stairs rust quickly near the ocean?

Not if the finish suits the site. Galvanising provides a zinc layer that corrodes first, and a topcoat can add another barrier. Regular rinsing helps remove salt deposits. If parts of the stair sit in constant spray or stay damp, stainless steel may be the better option.

3. Are metal stairs noisy?

They can be if they are under-built or poorly fixed. Thin treads can vibrate, and loose bolts can creak. Fabricators reduce this with stiffened treads, solid stringers, and tight connections. Small details such as rubber pads at contact points can also reduce vibration and rattle. Ask your supplier how they manage vibration in the design.

4. Are metal stairs safe in wet weather?

Yes, when the tread surface is chosen for grip. Outdoor stairs often use grating, serrated edges, or textured plate. Good lighting and a continuous handrail also matter. Indoors, slip-resistant nosings or tread covers can improve traction without changing the frame. Safety also improves when tread heights stay consistent over time.

5. What should I ask about staircase installations?

Ask what corrosion protection is specified (galvanising, coating system, or stainless grade) and how the design avoids water traps. Ask about tread slip resistance, handrail height, and how the stair will be anchored to the structure. A good provider will also explain cleaning and touch-up steps, plus what to check after storms.